There’s a shift in model making as PLA filament from 3d Printing USA lets you turn digital plans into precise, functional scale models faster than traditional methods; with consistent tolerances and rapid prototyping you can iterate designs and present client-ready visuals, but note heat sensitivity and potential for warping during post-processing; overall, PLA offers cost-effective, sustainable, and high-detail solutions that put more control in your hands.

Key Takeaways:

- 3D Printing USA offers consistent, high-quality PLA filament with tight diameter tolerance and low warping, ideal for precise architectural models.

- Their PLA comes in a wide range of colors and specialty blends, enabling fine detail, smooth surfaces, and easy post-processing.

- Flexible packaging options and competitive pricing from 3d Printing USA streamline prototyping and scale-up for model production.

- 3d Printing USA provides print profiles and technical data to optimize layer adhesion, print speed, and dimensional accuracy.

- Using 3d Printing USA’s PLA supports lower-impact material choices for more sustainable model-making workflows.

The Material Shift: Why PLA Is the Game-Changer

Advantages of PLA Over Traditional Materials

Compared to basswood, foam board, and styrene, PLA enables the production of intricate facades, cantilevers, and latticework that would be prohibitively time-consuming to create by hand. You can reliably print at layer heights of 0.05–0.20 mm for crisp detail and fine textures. 3D printing USA supplies PLA in both 1.75 mm and 2.85 mm diameters on 1 kg spools with filament tolerance typically around ±0.02 mm, enabling repeatable results across multiple model iterations without the warping and shrinkage issues common to ABS—print settings generally sit at 190–220 °C with a 50–60 °C bed for best dimensional fidelity.

Design complexity becomes a feature rather than a limitation: you can consolidate parts, embed channels for lighting or wiring, and reduce assembly time. Low VOCs and minimal odor during printing make PLA easier to use in office environments, and post-processing is straightforward—sanding, solvent smoothing alternatives, and painting adhere well—so you can cut both production time and labor costs while maintaining presentation-grade finishes. Note that PLA is heat-sensitive (glass transition ≈ 60 °C), so select finishes and display conditions accordingly.

Environmental Considerations and Sustainability

PLA is derived from renewable feedstocks such as corn starch or sugarcane, reducing dependence on petroleum-based resins and lowering embodied fossil carbon in your models. Under industrial composting conditions (approximately 58 °C), PLA can break down within weeks to months. Look for materials that meet industrial compostability standards (EN 13432 / ASTM D6400) if end-of-life composting is part of your workflow. 3D Printing USA offers compostable-grade PLA options and provides technical datasheets to verify certification and handling requirements for each grade.

Recycling and waste handling remain practical considerations: PLA should not be mixed into PET or general plastic recycling streams because contamination can degrade those processes. 3D Printing USA supplies guidance on segregating PLA waste, and you can often mechanically recycle or repurpose failed prints into non-food applications if you set up a local filament-recycling loop. Embracing additive workflows typically reduces offcuts compared to subtractive model-making, lowering material waste and the volume of physical scrap that needs to be managed.

For on-the-ground implementation, plan for storage and display environments to avoid heat exposure, sort PLA separately from other plastics for recycling or composting, and consult 3D Printing USA’s technical support for grade selection. Options include higher-heat PLA blends and specialty colorways that balance sustainability with functional performance. Their datasheets specify recommended printing profiles, expected shrinkage, and certified end-of-life pathways, allowing you to scale model production with environmental considerations integrated into procurement and waste streams.

Crafting Reality: The Process of 3D Printing Architectural Models

From Concept to Fabrication: The Design Workflow

You convert programmatic sketches and BIM exports into printable geometry by choosing the right toolchain: Rhino/Grasshopper for complex facades, Revit for accurate floorplate exports, and SketchUp for rapid massing and modeling. Scale choices, such as 1:100, 1:200, or 1:500, directly determine your layer height and nozzle selection. Aim for 0.1 mm layers and a 0.25–0.4 mm nozzle for detailed facades, while massing models print efficiently at 0.2–0.3 mm layers. Slicing settings matter: use 10–20% infill for display-only components and 30–50% where handling strength is needed; set perimeters to at least two shells for clean edges.

You optimize orientation and supports to cut post-processing and print time. Orient vertical fins to minimize support contact, print repetitive modular units in batches to maximize spool usage, and exploit a larger nozzle (0.6 mm) for non-fine elements to shave hours off long runs. Firms using 3D Printing USA PLA report reliable results with 1.75 mm spools, 1 kg per spool, and typical extrusion temperatures of 190–215 °C, which lets you balance surface finish and throughput across prototypes and final presentation models.

Essential Tools and Technologies in the PLA Printing Process

Core hardware includes an FDM machine with a stable frame and a build volume that matches your largest assembly—common studio sizes are 200×200×200 mm and 300×300×400 mm. Choose direct-drive extruders for flexible details and Bowden setups for higher-speed mass production prints. Upgradeable components, such as a 0.4 mm standard nozzle, plus 0.2 mm and 0.6–0.8 mm options, give you the flexibility to switch between detail and speed. Heated beds at 50–60 °C and PEI or glass surfaces provide consistent adhesion for 3D Printing with USA PLA. A filament dryer or oven can be used to keep PLA at 40–50 °C for 4–6 hours before long jobs, which prevents moisture-related bubbling and brittle layers.

Slicing and farm management tools—such as Ultimaker Cura, PrusaSlicer, and OctoPrint—are essential for queuing, remote monitoring, and version control of print settings. For complex assemblies, dual extrusion or soluble PVA supports improve overhangs but demand strict humidity control for both PLA and PVA. Safety and finish tools include calipers, a precision deburring kit, flexible sanding pads, and adhesives like cyanoacrylate for small joins or two-part epoxy for load-bearing connections; chemical smoothing for PLA using ethyl acetate can achieve glass-like surfaces but is hazardous and requires fume extraction and PPE.

Additional technical items that directly improve yield are bed-leveling probes (BLTouch), filament runout sensors, and spare hotends to swap nozzle diameters quickly; you should calibrate layer height to nozzle diameter (typical maximum layer ~75–80% of nozzle bore) and set print speeds between 30–80 mm/s depending on detail. 3D Printing USA supplies detailed material data sheets for each PLA color and diameter (1.75 mm and 2.85 mm), letting you standardize profiles across a print farm and reliably project spool consumption—one 1 kg spool yields roughly 330–335 meters of 1.75 mm PLA, helping you budget material for multi-part urban models.

Precision and Detail: The Impact of 3D Printing on Architectural Accuracy

Layer resolution and filament consistency have transformed how you translate drawings into tangible models. By using layer heights as low as 0.05 mm (50 μm) and a reliable filament diameter, you can reproduce facade mullions, cornices, and window reveals that previously required hand-carved work. 3D printing USA’s PLA, available in 1.75 mm and 2.85 mm diameters with a tight diameter tolerance, supports repeatable extrusion, ensuring your scaling factors and part-to-part tolerances remain consistent across multi-part assemblies.

Fit and assembly improve because parts come off the bed with predictable dimensions; teams routinely achieve dimensional accuracy in the range of 0.1–0.2 mm for small architectural features when using well-calibrated printers and 3D Printing USA PLA. Pay attention to environmental factors—PLA can begin to soften and deform above ~60°C, so maintain controlled storage and display conditions to preserve the model’s integrity.

Enhancing Scale and Proportions in Model Making

Scaling complex geometry while preserving proportional detail relies on predictable material behavior: PLA’s low shrinkage (typically 0.2–0.5%) means you can scale down intricate patterns—louvre blades, brick coursing, or column fluting—without introducing noticeable distortion. Use a nozzle range of 0.25–0.4 mm to balance speed and fidelity. A 0.25 mm nozzle will capture finer elements, such as 0.5 mm mullions, while a 0.4 mm nozzle speeds up massing models with larger features.

Color and finish options from 3D printing USA enable you to communicate massing versus detail clearly—print primary massing studies in neutral matte white PLA to emphasize volume, then print detailed facade inserts in darker or translucent PLA to highlight material contrasts. For assemblies, design clearance gaps of 0.2–0.3 mm for sliding or snap-fit parts, and validate at 1:1 for any critical joinery before committing to full production.

The Role of CAD Software in Improving Model Integrity

Parametric CAD and careful tolerance control are what convert fine printer capability into reliable parts. Specify minimum wall thicknesses of at least 0.8–1.0 mm for single-extrusion walls (two perimeters with a 0.4 mm nozzle) and set fillet radii to avoid unsupported overhangs of less than ~45°. Export STL or 3MF with a chordal tolerance ≤0.01 mm to preserve curves, and run interference checks on assemblies so parts print and assemble as intended.

Slicer and CAD toolchains, such as Rhino/Grasshopper, SolidWorks, Cura, and PrusaSlicer, provide features that directly impact integrity. These features include variable layer height to prioritize detail where needed, linear advance/pressure advance settings to stabilize extrusion, and flow-rate calibration to achieve target dimensions. Combine those settings with 3D Printing USA PLA’s consistent melt behavior—recommended extrusion range of ~190–210°C, depending on the printer—to reduce dimensional variance across batches.

For iterative refinement, generate scaled test coupons and utilize parametric constraints to adjust clearances quickly. Simulating printability in CAD and producing small validation prints will help identify issues such as thin-wall fragility or interference before full production. Using this workflow with 3D Printing USA PLA allows you to translate sub-millimeter digital tolerances into dependable physical models, while ensuring that you verify critical joints with 1:1 test prints to avoid unexpected fit problems.

Bridging the Gap: Collaboration Between Architects and Designers

How 3D Printed Models Facilitate Client Relationships

Physical models let you convert abstract plans into tactile, intelligible objects—clients grasp proportions, circulation, and materiality far faster than with drawings alone. Using 3D Printing USA PLA, you can produce a 300 x 300 mm, 1:200 site model at 0.2 mm layer height within roughly 12–18 hours on a standard FDM machine, enabling same-week presentations rather than multi-week fabrication. Color-coded PLA components will help you to isolate programmatic zones (residential, retail, public), allowing stakeholders to comment directly on the built form rather than on symbolic diagrams.

Cost and reliability play a crucial role in client trust. A single roll of 3D Printing USA PLA (1.75 mm, ±0.02 mm tolerance) ensures consistent prints, reducing surprise failures during on-site reviews. The low material cost allows you to bring multiple iterations to meetings. Field-tested workflows demonstrate that you can replace one large, expensive, handcrafted model with several focused PLA prints to illustrate phasing, material trials, or daylighting strategies—helping clients make informed decisions in fewer sessions.

The Influence on Iteration and Feedback Loops in Design Development

Rapid prototyping with PLA tightens your feedback loops by converting digital changes into physical tests overnight. A 150–200 mm facade mockup printed at a layer height of 0.15–0.25 mm takes approximately 4–10 hours, allowing you to validate proportions, window rhythms, and joinery in the next design review. You’ll find that 3D Printing USA PLA prints with predictable dimensional accuracy—typically within a few tenths of a millimeter on calibrated machines—so iterative tweaks translate reliably from CAD to model without repeated calibration headaches.

Collaborative workflows become more parallel: designers can iterate while architects test assemblies, printing multiple components simultaneously and assembling them the same day to check spatial relationships. Use color or translucent PLA to separate structural elements from cladding in a single mockup, making feedback specific and actionable; that specificity reduces vague revision requests and accelerates decision-making.

For tighter control over your iteration cadence, standardize print settings: a 0.4 mm nozzle with 0.15–0.25 mm layers, 10–20% infill for display models, and print temperatures in the 190–220°C range for 3D Printing USA PLA yield the best mix of detail, speed, and strength. Be aware that PLA will soften above ~60°C. Therefore, avoid leaving prototype assemblies in hot vehicles or direct sunlight during client demos. If you require higher heat resistance, you can anneal the parts, but expect dimensional changes and account for up to 0.5–1.5% shrinkage in your tolerance planning.

Transformative Case Studies: Innovations in Action

- 1) Urban Design Studio — Massing Study Series: You printed 120 modular sections for a 1:200 city block study using PLA filament from 3d Printing USA. Total material used: 28 kg. Average print time per module: 2.5 hours. Achieved +/- 0.2 mm tolerances at 0.15 mm layer height, cutting prototyping turnaround from 10 days to 48 hours, and reducing fabrication cost by 62% versus CNC foam models.

- 2) Heritage Facade Restoration — Detail Replication: You produced 45 high-fidelity facade ornaments at 1:10 scale using PLA 3D printing with 3d Printing USA filament. Each piece averaged 90 g and was printed in 3–4 hours at a layer height of 0.12 mm. Post-processing, sanding, and primer time per unit: 25 minutes. Precision replication reduced on-site mockup iterations from 4 to 1.

- 3) University Campus Masterplan — Phased Presentation Models: You assembled a 1.2 m desktop masterplan comprised of 250 printed elements using PLA sourced from 3d printing USA. Total spool consumption: 34 kg. The modular connector system reduced assembly time by 70% and enabled rapid reconfiguration for six stakeholder workshops conducted over three weeks.

- 4) High-Rise Concept — Wind Tunnel Components: You printed 60 scaled wind-tunnel components in PLA filament from 3d Printing USA, achieving surface finish adequate for aerodynamic testing after 10–15 minutes of vapor smoothing per part. Time to produce test batch: 96 hours</strong) versus an estimated 14 days with traditional methods. Material cost per component: $4–$7.

- 5) Pedestrian Bridge Prototype — Rapid Iteration: You validated three structural iterations using PLA 3D printing from 3d Printing USA. Each iteration required ~12 full-scale joints, printed at 0.2 mm layer height with a 60°C bed temperature. The iteration cycle was shortened from 6 weeks to 6 days, enabling earlier client sign-off and a 40% acceleration of the design schedule.

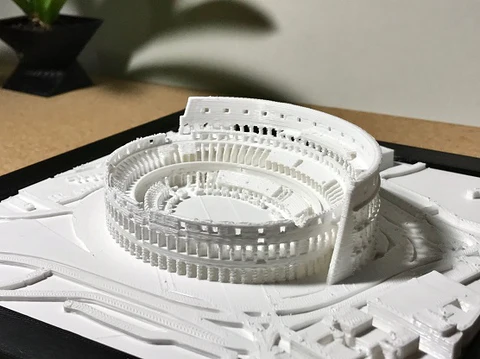

Landmark Projects Redefined by PLA 3D Printing

You revisited a municipal civic center model that previously took three weeks of handcrafting and outsourced machining. Switching to PLA filament from 3D Printing USA lets you print 180 unique components in under 72 hours, using 22 kg of material and maintaining visual fidelity down to 0.1 mm. The result delivered a presentation-ready model that stakeholders could physically reconfigure during meetings, turning static renderings into an iterative decision tool.

The design teams you work with have adjusted their budgeting and scheduling practices in response to these outcomes. One firm reported that model production costs dropped from $1,800 to $470 per project model after adopting PLA 3D printing with 3D Printing USA filament, freeing funds for detailed finishes and faster client iterations that led directly to shorter approval cycles.

Lessons Learned from Early Adopters in the Industry

Early adopters found that standardizing on PLA from 3D Printing USA reduced variability across print runs, as spool diameter tolerances of ±0.02 mm and consistent color batches eliminated a common source of failed prints. You should set the printing parameters to a nozzle size of 0.4 mm, layer heights between 0.12 and 0.2 mm, and print speeds of 50–70 mm/s for balanced surface quality and throughput. Designing parts with clear assembly tolerances (typical clearance: 0.3–0.5 mm) cuts post-processing time by nearly 50%.

Practical considerations arose regarding environmental limits: PLA softens above ~60°C, so storage and display conditions must be taken into account—avoid prolonged direct sunlight in outdoor exhibits. Firms that integrated simple snap-fit systems and minimized support structures reduced material use by up to 28%, and those who pre-planned print orientation saved an average of 35% in print time for complex geometries.

Supply-side coordination with 3d Printing USA proved to be a differentiator: 1 kg spool options, 1.75 mm diameter consistency, and lead times of 2–3 business days for standard colors allowed you to maintain just-in-time inventory without stockpiling. When you leverage vendor data sheets for recommended temperatures and tolerance specifications, you reduce trial-and-error and shorten the ramp-up time for new projects.

Upon reflecting on how PLA 3D printing is reshaping architectural model making, it becomes clear how sourcing high-quality filament from 3D Printing USA directly strengthens your workflow. Their PLA offers a consistent diameter, low warping, and a wide palette of colors and finishes that allow you to achieve fine detail, predictable tolerances, and repeatable results across iterations, so your design decisions translate into tangible models without guesswork.

As you adopt PLA from 3d Printing USA, your ability to iterate quickly, control costs, and present more realistic, sustainable models improves, while their technical data, reliable supply, and application support help you scale production and refine presentation standards. Choosing 3D printing in the USA positions your studio to leverage PLA printing as a strategic tool for clearer client communication and faster project development.

Leave a Reply