In plumbing and hydraulic systems, choosing the right fitting is crucial for ensuring secure, leak-proof connections. Two widely used thread standards are British Standard Pipe Parallel (BSPP) and National Pipe Tapered Fuel (NPTF). These standards are particularly important when converting between British and American systems. The 9007BSPP to NPTF fitting is essential for facilitating compatibility between these different standards, making it invaluable in various industries.

This guide delves into the intricacies of these thread types and the role of the 9007BSPP to NPTF fitting in connecting them.

What is a BSPP Fitting?

BSPP, or British Standard Pipe Parallel, is a threading standard from the UK, commonly used across Europe and other regions. BSPP fittings feature straight, non-tapered threads, differentiating them from BSPT (British Standard Pipe Tapered) or NPTF threads. In BSPP fittings, a tight seal is typically achieved with additional components like O-rings or washers, rather than the threads alone.

The 9007BSPP to NPTF fitting enables BSPP fittings to connect with systems using NPTF threads, accommodating the differences in thread design and sealing mechanisms.

What is an NPTF Fitting?

NPTF, standing for National Pipe Tapered Fuel, is a common thread standard in the United States. Unlike BSPP, NPTF fittings have tapered threads, meaning the diameter of the threads decreases along the length of the fitting. This design allows NPTF fittings to create a “dry seal,” where the threads compress to form a seal without needing additional materials like tape or sealant.

The 9007BSPP to NPTF fitting is essential when adapting BSPP-threaded components to NPTF systems, which is often necessary in global hydraulic systems or machinery that spans different countries.

The Importance of Thread Compatibility

Thread compatibility is crucial in hydraulic systems to prevent leaks, system failure, and safety risks. The 9007BSPP to NPTF fitting ensures that British BSPP components can seamlessly integrate with American NPTF components, allowing for a secure and efficient connection between different international standards.

Where 9007BSPP to NPTF Fittings Are Used

These fittings are commonly used in industries such as manufacturing, automotive, and aerospace, where hydraulic and pneumatic systems require reliable connections. Given the global nature of trade, European products using BSPP fittings often need to be compatible with American NPTF-threaded infrastructure. The 9007BSPP to NPTF fitting makes this possible, facilitating global trade and machinery integration without compromising system integrity.

How 9007BSPP to NPTF Fittings Work

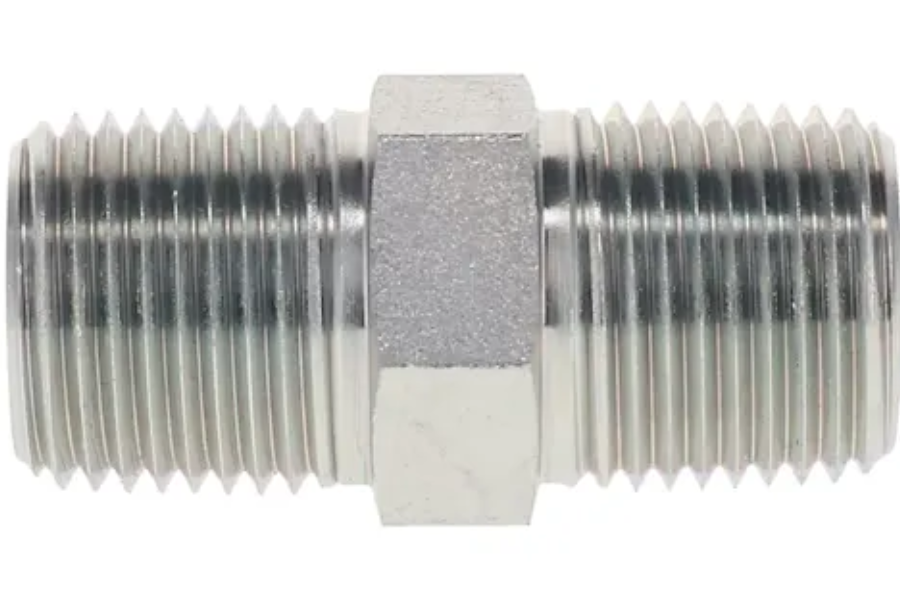

The 9007BSPP to NPTF fitting acts as an adapter, with one end featuring BSPP threads and the other NPTF threads. This design allows smooth integration of different thread types within a single system. Proper installation is key to creating a secure seal, with the BSPP end usually requiring additional sealing materials like O-rings, while the NPTF end achieves a dry seal through its tapered design.

Why the 9007BSPP to NPTF Fitting is Critical for Global Operations

In today’s globalized market, machinery is often built in one country and used in another, where different engineering standards apply. For example, European equipment may use BSPP fittings, while American infrastructure is designed for NPTF threads. The 9007BSPP to NPTF fitting enables these international components to work together seamlessly, eliminating the need for costly modifications or replacements.

Common Issues with Thread Conversion

While the 9007BSPP to NPTF fitting provides a convenient solution for thread conversion, it is not without challenges. Common issues include improper alignment of threads during installation, leading to leaks or system failure. Additionally, using the correct sealing materials is critical—while the NPTF end does not require additional seals, the BSPP end typically does, and using the wrong sealant can result in connectio

These fittings are typically made from durable materials like stainless steel, brass, or carbon steel, chosen for their ability to withstand high pressures and corrosive environments. The selection of material should be based on the specific application and environment in which the fitting will be used. For instance, stainless steel fittings are ideal for corrosive environments, while brass fittings may be sufficient for less demanding applications.

Selecting the Right 9007BSPP to NPTF Fitting

When selecting a 9007BSPP to NPTF fitting, consider factors such as pressure rating, temperature range, and material compatibility. The fitting must meet the specific demands of the application to ensure safety and reliability. Additionally, the fitting size must match the components it connects; mismatched sizes can lead to leaks or system failure.

Conclusion

The 9007BSPP to NPTF fitting is crucial for industries that require the integration of British and American thread standards. Whether in hydraulic systems, plumbing, or fuel lines, this fitting provides a reliable solution for connecting incompatible threads. By understanding the differences between BSPP and NPTF threads and the importance of thread compatibility, you can ensure the success of your projects and operations.

Explore essential insights and updates at mydmc sso.

Leave a Reply